Static Control Material

Anti ESD Coating

For FPD manufacturing process

NF-685B/NF-685/NF-718ECB

Keeping static charge by delamination lower for a long period and protecting a glass softly.

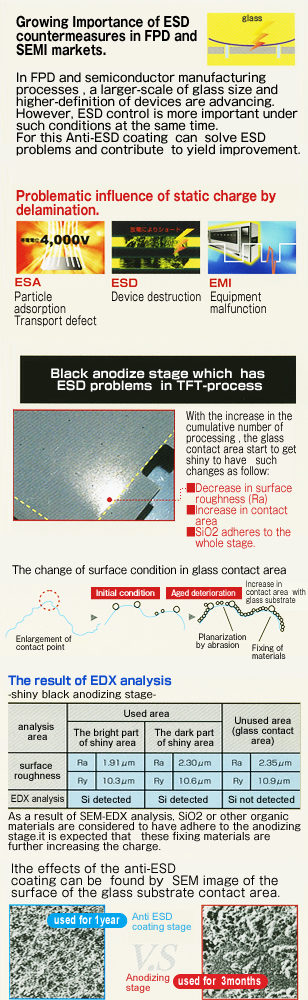

- It controls static charge by delamination for its lower adsorption energy,

- This coating is conductive. So it is free from getting charged without giving a bad influence on a glass panel.

- Reducing stuck material caused by contamination on glass backside.

- Shortened the tact time for lifting

- Protecting a glass softly

- Improved alignment performance by better slippage

- Long lifetime. No ESD problem occurring of from delamination even during longtime use.

| High quality coating in clean room area |

- Coating in clean room area to prevent the contamination and inclusion to the coating.

- Prevent damage to a glass from stuck material at vacuum chucking.

| Coating for high-definition and large-size glass |

- Accomplishment of lower flatness by the established framework of our original processing technique.

- Established framework of the processing technique based on longtime experience and good delivery records.

- Accomplishment of highly accurate and large-scale stage(G8) manufactured by high-accurate base material and fabricating technique.

Sales result

| Stage size | flatness |

| 320×15mm | 10μm |

| 730×920×30mm | 10μm |

| 1,500×1,500×30mm | 20μm |

| 2,280×2,280×30mm | 20μm |

Specification

| Model | color | coating-thickness | feature |

| NF-685B | Black | 30μm | standard-model |

| NF-685 | White | 40μm | standard-model |

| NF-718ECB | Black | 2mm | Super thick model for second processing |